Among the naysayers challenging the legitimacy of low volume sand casting are concerns about its dimensional accuracy and surface finish compared to high-volume processes. Advances in technology, particularly with the integration of 3-D printing for mold creation and computer-aid simulation for flow dynamics, have significantly mitigated these concerns. These innovations provide precise mold designs and enhance the predictability of pour patterns, resulting in better final product quality and reduced need for costly post-processing. Trustworthiness in the field of low volume sand casting is not just about consistency in product delivery but extends to adherence to environmental and safety standards. The process inherently has a lower environmental footprint compared to other casting techniques. The sand used in molds can often be reused, and the operational energy demands are typically less intensive, aligning well with modern green manufacturing principles. In the ever-evolving landscape of manufacturing, low volume sand casting stands out by promising high quality, innovative adaptability, and cost control. With a legacy that underscores reliability and flexibility, it provides a platform upon which businesses can construct tailored manufacturing solutions without compromise on quality or budget limits. In recognizing these strengths, industries are increasingly leveraging this time-honored method to project ideas from the drawing board into tangible, market-ready products, ensuring competitive advantage while fostering sustainable practices. Post time:1 月 . 15, 2025 10:01

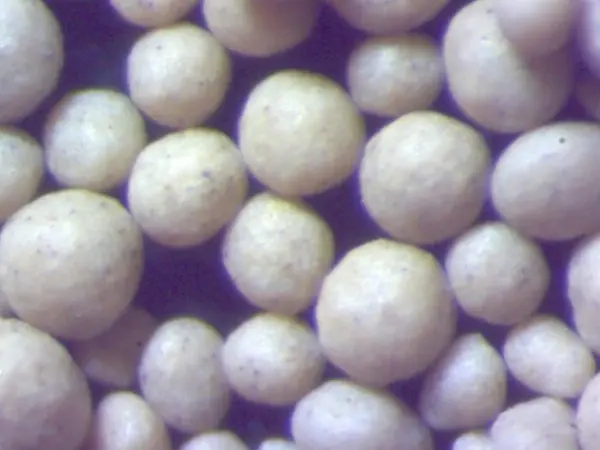

Next:Sintered ceramic sand made in China same with Cerabeads AFS 60