Authoritativeness in iron sand casting is demonstrated through a track record of successful project completions, often showcasing innovation and problem-solving prowess. Companies that have cemented their authority in this arena are typically characterized by their commitment to quality assurance processes, adherence to strict safety standards, and continuous investment in latest technology and training. Trustworthiness in the context of iron sand casting is cultivated through transparent operations and responsive customer relations. Reliable manufacturers communicate openly about production timelines, potential challenges, and cost implications, fostering a relationship of trust with their clients. Additionally, sustainability practices, such as reusing sand and minimizing waste, further enhance trust by aligning with global environmental priorities. In conclusion, iron sand casting represents a dynamic interplay of tradition and modernity, requiring a nuanced blend of experience, expertise, authoritativeness, and trustworthiness. As industries continually seek innovative and reliable manufacturing solutions, those who master the complexities of iron sand casting will invariably lead in the creation of high-quality, enduring products that stand the test of time. Post time:1 月 . 15, 2025 10:00

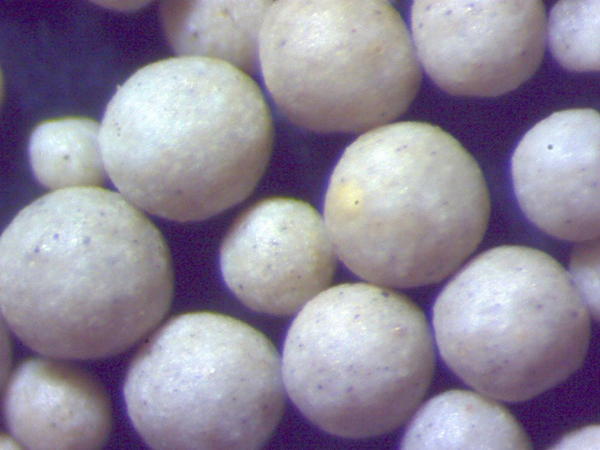

Next:Spherical Ceramic Sand for Foundry