Materials Used for Sand Casting

Sand casting is one of the oldest and most widely used metal casting processes, allowing for the production of complex shapes with high accuracy. It involves a variety of materials, each contributing to the final product’s quality, strength, and integrity. This article explores the key materials used in sand casting and their significance in the casting process.

1. Sand

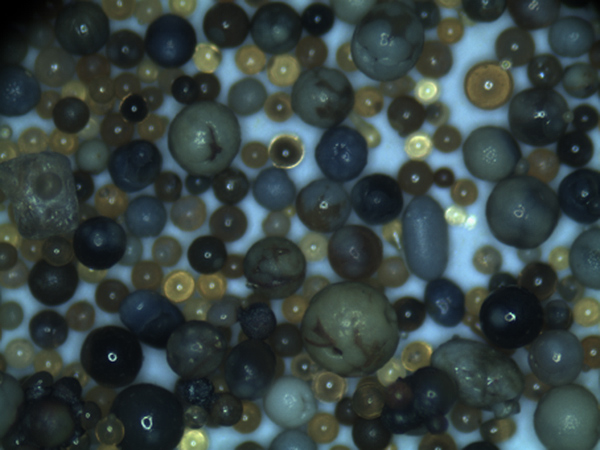

The primary material in sand casting is the sand itself. The most commonly used type is silica sand, which consists primarily of silicon dioxide (SiO2). The grain size, shape, and distribution of the sand grains significantly influence the properties of the final casting.

- Grain Size Fine grains provide better detail, while coarse grains are used for larger, less detailed castings. A mixture of different grain sizes can be used to optimize the mold’s strength and surface finish. - Shape and Composition The shape of the sand grains affects the mold’s permeability and compaction. Round grains are easier to compact but do not hold moisture as well as angular grains, which have a higher surface area.

To enhance the properties of sand for casting, additives such as clay (often bentonite) are mixed in to improve the binding properties and strengthen the mold. The clay helps hold the sand grains together, forming a bonded mold that can withstand the fusion of molten metal.

2. Binders

Binders are materials added to the sand to improve its cohesiveness and stability. The most common binders in sand casting include

- Clay Bentonite clay is widely used due to its excellent binding properties. It absorbs water and expands, helping to hold the sand grains together, thus forming a strong mold that can withstand the pouring of molten metal.

- Resin In addition to traditional clay binders, thermosetting resins are also used in modern sand casting. These resins can provide better accuracy and surface finish compared to clay-bound sand. They harden upon heating and can create thin-walled and intricate designs.

3. Metal Alloys

The choice of metal alloy is critical in sand casting as it determines the desired properties of the final product. Common metals used in sand casting include

- Aluminum Alloys Lightweight and corrosion-resistant, aluminum alloys are popular in automotive and aerospace applications

. They can be cast with great precision and offer a good surface finish.what materials are used for sand casting

- Iron Alloys Cast iron is another commonly used material, favored for its excellent casting properties and machinability. It is durable and can handle high stresses, making it suitable for heavy machinery and automotive parts.

- Copper Alloys These alloys, including bronze and brass, offer excellent conductivity and corrosion resistance, making them ideal for electrical components and maritime applications.

- Steel Alloys Carbon and low-alloy steels are used for structural components due to their strength and toughness. However, they require careful temperature control during casting to avoid defects.

4. Core Materials

In many sand casting processes, cores are used to create internal cavities or complex geometries that cannot be formed from the mold alone. Core materials are specifically designed for strength and compatibility with the casting process. Common materials for cores include

- Sand Cores These are made similarly to the mold's sand, often using a higher concentration of binder for added strength.

- Soluble Cores Special soluble materials can be used to create internal passages and can be removed easily after the casting process, allowing for complex designs.

- Metal Cores In some cases, pre-cast metal cores are used, particularly in high-performance applications where a stronger internal structure is necessary.

5. Release Agents

To assist in the easy separation of the mold and the finished casting, release agents are often applied to the mold surfaces. These agents create a barrier between the sand mold and the molten metal, preventing adhesion and facilitating mold removal while ensuring a smooth surface finish.

Conclusion

The materials used in sand casting play a crucial role in determining the quality and characteristics of the final product. From the sand and binders that form the mold to the metal alloys poured into it, each component is essential for the successful completion of the casting process. Understanding these materials and their properties helps manufacturers optimize their sand casting operations, leading to innovative designs and high-performance products. The versatility and adaptability of sand casting continue to make it a staple in various industries, showcasing the importance of selecting appropriate materials.

Post time:10 月 . 12, 2024 01:59

Next:how sand casting works