Sanding Small 3D Prints A Comprehensive Guide

3D printing opens up a world of creativity, allowing hobbyists and professionals alike to bring their digital designs into the physical realm. One of the critical steps in achieving a polished and professional look for your 3D prints is sanding. While it may seem daunting, sanding small 3D prints can enhance their aesthetic appeal and prepare them for painting or other finishing processes. This article provides a comprehensive guide on how to effectively sand your small 3D prints.

Understanding the Need for Sanding

When you remove a 3D print from the printer, it often has visible layer lines. These lines can detract from the visual quality of the final product, especially for intricate designs or functional parts. Sanding helps to smooth these layer lines and can also eliminate any rough patches from the printing process, resulting in a more refined appearance.

Choosing the Right Tools and Materials

To effectively sand your 3D prints, you will need some essential tools

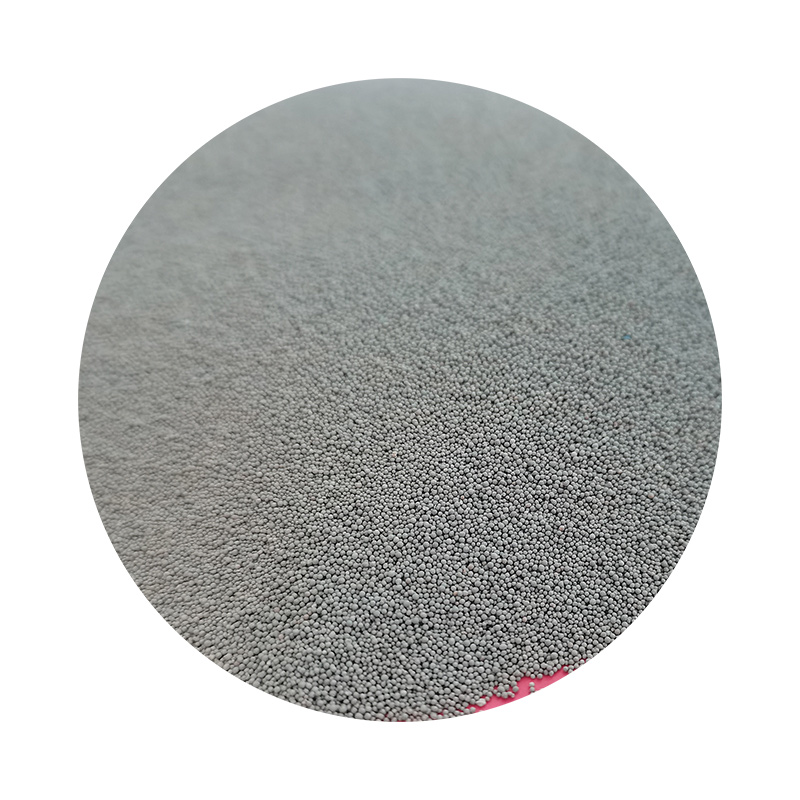

1. Sandpaper Start with coarser grits (around 100-200) and gradually move to finer grits (400-1000). Using a progression of grits allows for smoother finishes.

2. Sanding Block or Sponge A sanding block can help maintain even pressure, particularly on flat surfaces. For curved or detailed areas, a sanding sponge may be more effective.

3. Water Wet sanding, or using water while sanding, can reduce dust and prevent the sandpaper from clogging, allowing for a smoother finish.

4. Protective Gear Always wear a mask and safety goggles to protect against fine dust particles created during sanding.

sanding small 3d prints

Step-by-Step Sanding Process

1. Preparation Begin by inspecting your print for any supports or artifacts that need to be removed. Use tools like clippers or a craft knife to eliminate these imperfections.

2. Start with Coarse Sandpaper Begin with a coarser grit sandpaper. Focus on areas with the most noticeable layer lines. Sand evenly in circular motions or along the grain of the print until the rough spots begin to smooth out.

3. Transition to Finer Grits Once you have smoothed out the major imperfections, switch to a finer grit sandpaper. This step will help eliminate any scratches left by the coarser paper and will refine the overall finish.

4. Wet Sanding (Optional) If you prefer, you can wet sand using water. Dip your sandpaper in water to reduce friction and dust. Remember to rinse and clean the prints periodically to remove sanding residue.

5. Final Touches After sanding to your satisfaction, ensure the print is clean and free of dust. You can use a damp cloth to wipe it down before any painting or finishing.

Tips for Successful Sanding

- Take Your Time Rushing through the sanding process can lead to uneven surfaces. Patience results in a higher quality finish. - Inspect Frequently Regularly check your print to gauge improvements and avoid over-sanding any areas. - Experiment with Finishes Once you have sanded your print, consider applying primer or paint. Sanding not only improves appearance but also helps paints and coatings adhere better.

Conclusion

Sanding small 3D prints is a valuable skill for anyone looking to enhance their 3D printing projects. By following the steps outlined in this guide and using the right tools, you can transform your prints from rough to refined, unlocking their full potential. Happy sanding!

Post time:10 月 . 02, 2024 17:07

Next:sand casting steel