The Versatility of Sand Casting in Modern Manufacturing

Sand casting, a time-honored metal casting process, remains one of the most widely used methods for the production of complex metal components. Its advantages in terms of flexibility, cost-effectiveness, and the ability to produce intricate designs make it a favored choice in various industries, ranging from automotive to aerospace. In this article, we will explore the diverse applications of sand casting and why it continues to thrive in modern manufacturing.

Understanding Sand Casting

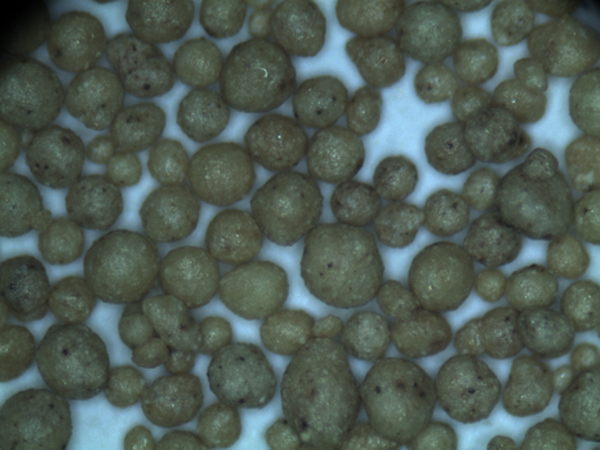

At its core, sand casting involves creating a mold from a mixture of sand, clay, and water. The process starts by forming a pattern, which is a replica of the desired object, using materials like wood or metal. The pattern is then placed in a sand mixture, where it forms a mold when the sand is compressed around it. Once the mold is completed, molten metal is poured in and allowed to cool and solidify. After solidification, the sand mold is broken away, revealing the finished piece.

Applications Across Industries

1. Automotive Industry One of the largest sectors utilizing sand casting is the automotive industry. Components like engine blocks, transmission housings, and various other parts are commonly manufactured using this method. Sand casting allows for the production of large and heavy parts that are necessary for vehicle functionality. Moreover, the ability to create complex geometries helps in reducing weight and improving overall efficiency.

2. Aerospace Industry The aerospace sector also significantly benefits from sand casting, particularly for producing components that require high precision and durability. Parts like turbine housings and brackets can be manufactured with intricate designs that meet stringent aerospace specifications. The ability to work with high-grade alloys and specialized materials allows for components that can withstand extreme conditions.

3. Marine Applications In the marine industry, sand casting is used to create various components such as engine mounts, pumps, and other structural parts that need to resist corrosion and wear due to harsh marine environments. The flexibility of sand casting allows manufacturers to produce parts in different sizes and complexities, meeting the diverse needs of marine vessels.

sand casting uses

4. Art and Sculpture Beyond traditional industrial applications, sand casting has also found its place in art and sculpture. Artists often utilize sand casting to create unique and intricate designs, allowing for a mix of creativity and material scope. The process enables the production of large sculptures and decorative accents that would be difficult to achieve through other methods.

5. Construction and Infrastructure Components such as manhole covers, structural beams, and architectural features can be manufactured through sand casting. The durability and strength of cast metal products make them ideal for construction, where they can withstand significant loads and harsh environmental conditions.

6. Medical Equipment The medical field has also started embracing sand casting for the production of various implants and prosthetics. The ability to customize shapes and sizes to fit individual needs is a valuable advantage in creating effective and comfortable medical solutions.

Advantages of Sand Casting

One of the standout features of sand casting is its cost-effectiveness, particularly for small to medium production runs. The materials required for sand casting are inexpensive, and the process is relatively simple compared to other casting methods. Additionally, because molds can be created quickly, manufacturing timelines can be reduced, allowing for a faster response to market demands.

Moreover, sand casting offers a high degree of design flexibility, enabling manufacturers to create complex shapes with intricate internal cavities. This characteristic is particularly beneficial in industries that require lightweight yet strong components, as it allows for optimized designs that enhance performance without compromising structural integrity.

Conclusion

In summary, sand casting is a versatile process that serves numerous industries. Its ability to produce complex and cost-effective components continues to make it a relevant choice in modern manufacturing. As technology advances and new materials are developed, sand casting is poised to remain a crucial part of the manufacturing landscape, adapting to meet the ever-evolving demands of various industries. Whether in rigorous applications like aerospace or artistic endeavors, the importance of sand casting is undeniably significant.

Post time:12 月 . 04, 2024 16:54

Next:Sustainable Practices for Reusing Foundry Sand in Industrial Applications