In addition to technical proficiency, trustworthiness and transparency in sourcing materials and managing the production process further emphasize the credibility of manufacturers specializing in sand cast iron. High-quality raw materials, adherence to industry standards, and thorough post-cast processes like cleaning, inspection, and machining are critical in establishing a reputation for reliability. These elements not only assure clients of consistent quality but also foster long-term partnerships. Moreover, as environmental considerations become increasingly critical in industrial processes, sustainable practices in sand casting iron are gaining prominence. Recycling sand and optimizing energy consumption in melting and pouring operations reduce the environmental footprint, aligning manufacturing practices with global sustainability objectives. Ultimately, the realm of sand casting iron merges traditional craftsmanship with cutting-edge technological advances. Expertise in this field is revealed through the careful orchestration of processes and materials that transform raw iron into intricate, durable components. As industries continue to demand high-quality, customized metal parts, sand casting remains an indispensable method, backed by its unbeatable combination of precision, adaptability, and sustainability. In an ever-evolving market, embracing these principles ensures that sand cast iron products not only meet but exceed modern performance and ethical standards. Post time:1 月 . 16, 2025 04:45

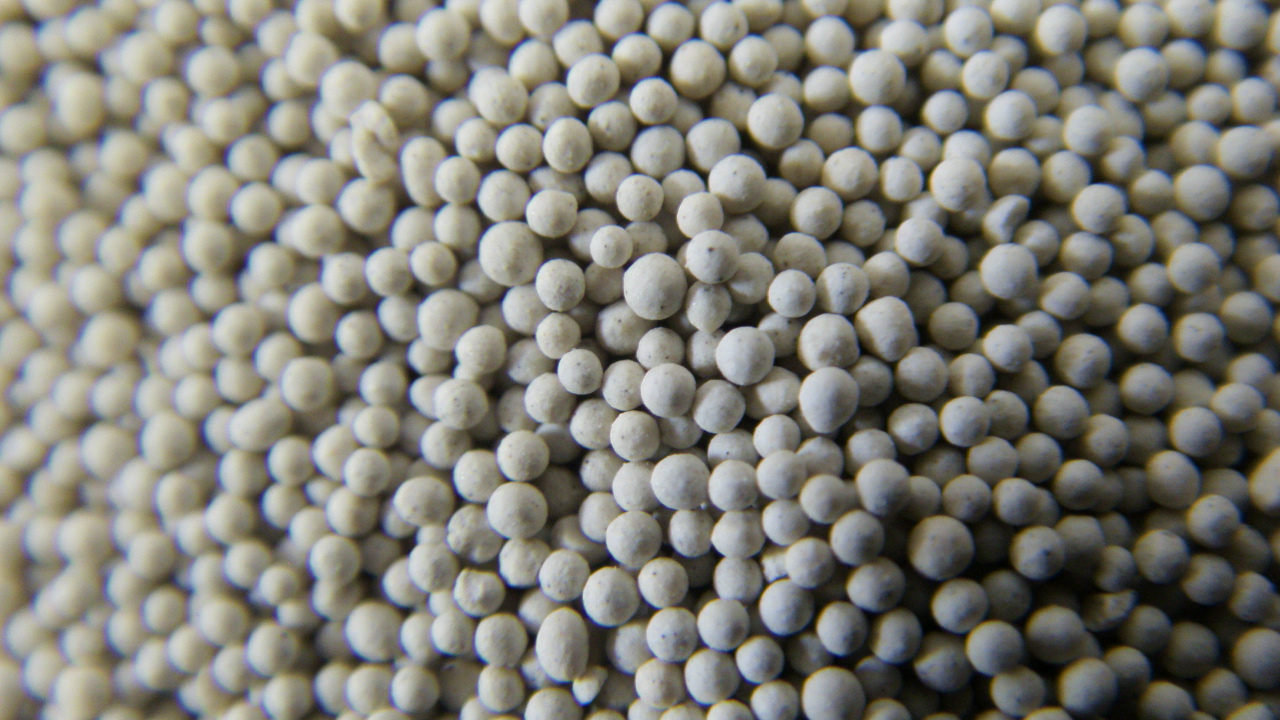

Next:Ceramic casting sand for sand 3d printing