The Rising Demand for Resin Coated Sand Suppliers

In the ever-evolving landscape of manufacturing and construction, the demand for high-quality materials is paramount. One such material that has gained significant traction in recent years is resin coated sand. This advanced product is essential in various industries, particularly in foundry applications, due to its exceptional properties that enhance casting quality and efficiency. As a result, the need for reliable resin coated sand suppliers has never been greater.

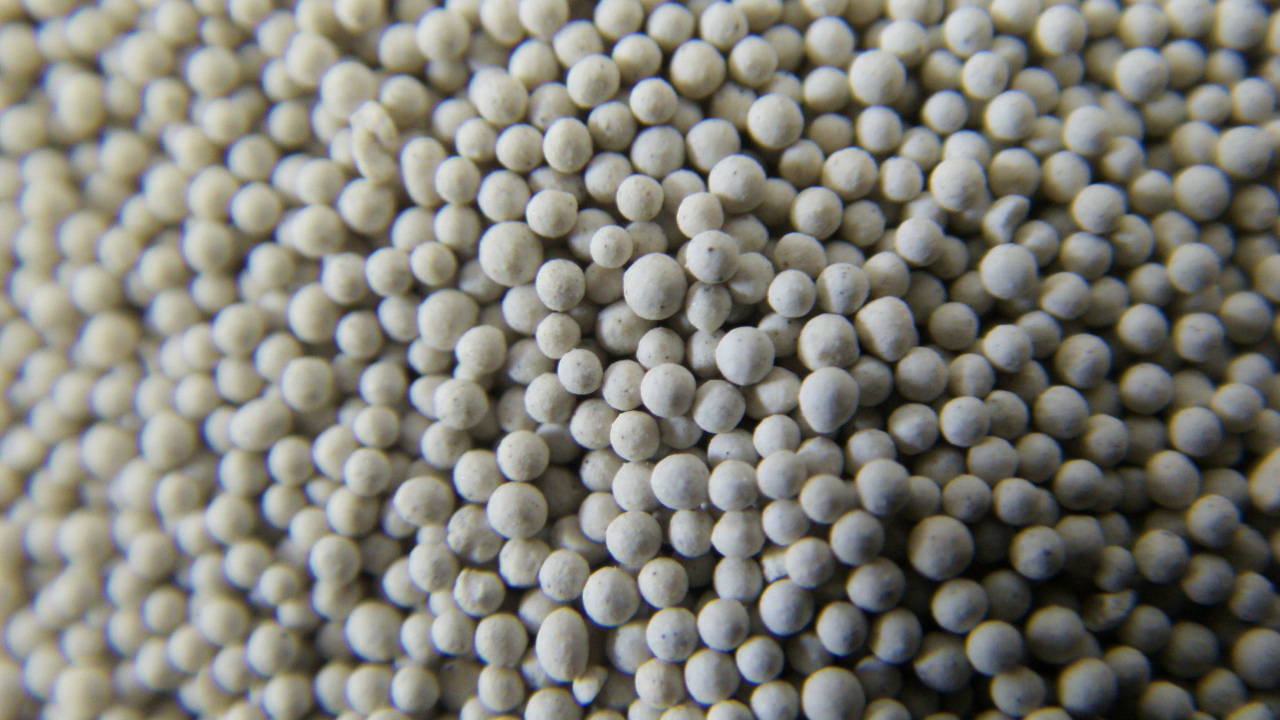

Resin coated sand is produced by coating silica sand grains with a thermosetting resin, which provides improved mechanical properties, reduced gas emissions, and better surface finish in casting processes. This is especially crucial in industries such as automotive, aerospace, and general manufacturing, where precision and strength are critical. With the increasing demand for lightweight and complex metal parts, manufacturers are turning to resin coated sand as a solution to meet stringent industry requirements.

The global market for resin coated sand is projected to grow steadily over the coming years. Various factors contribute to this growth, including the resurgence of the construction sector, advancements in automotive technologies, and an increase in investment in infrastructure projects. These developments necessitate an efficient supply chain and dependable partners, making the role of resin coated sand suppliers pivotal.

When selecting a resin coated sand supplier, several factors come into play. First and foremost, the quality of the product is essential. Suppliers must adhere to strict quality control measures to ensure that their resin coated sand meets industry standards. This includes not only the consistency and grade of the silica sand used but also the quality of the resin and the coating process.

resin coated sand suppliers

Moreover, the supplier’s ability to customize their offerings to meet specific customer requirements is a significant advantage. Industries often demand tailored solutions that cater to varying pouring temperatures and specific casting designs, making it crucial for suppliers to be flexible and innovative.

Another key consideration is the supplier’s production capacity and logistical capabilities. With the growing demand for resin coated sand, it’s essential to partner with suppliers who can scale their operations quickly and deliver products in a timely manner. Efficient logistics can streamline the supply chain, reducing downtime and ensuring that manufacturers have the materials they need when they need them.

In addition, sustainability has become a critical focus across industries. Suppliers that prioritize environmentally friendly practices, such as using eco-friendly resins and minimizing waste in their production processes, will likely have a competitive edge in the market.

In conclusion, as industries continue to evolve and demand more sophisticated solutions, the role of resin coated sand suppliers is becoming increasingly crucial. By providing high-quality products, flexible services, and sustainable practices, these suppliers are not only helping manufacturers improve their processes but are also contributing to the overall advancement of the industrial landscape. With the right partners, companies can successfully navigate the complexities of modern manufacturing and achieve their production goals.

Post time:11 月 . 02, 2024 21:11

Next:3d printer sand casting