Metal Sand Casting An Overview

Metal sand casting, also known as sand molding, is one of the most ancient and widely used metal casting processes. It involves creating metal parts by pouring molten metal into a mold made from sand. This process is favored for its versatility, cost-effectiveness, and ability to produce intricate shapes and large objects.

The Process of Sand Casting

The sand casting process begins with the creation of a mold. This is typically done using a mixture of sand, clay, and water, which gives the mold its strength and ability to retain its shape while holding the molten metal. The sand is compacted around a pattern—an object resembling the final product that is usually made of metal or wood. Once the sand is compacted, the pattern is removed, leaving a hollow cavity that will define the shape of the final casting.

Next, the metal to be cast is heated until it is molten. Common metals used in sand casting include aluminum, iron, and bronze, each chosen for their specific properties. Once the metal reaches the appropriate temperature, it is poured into the mold cavity through a series of channels and gates designed to facilitate the flow of the molten metal.

After the metal solidifies, the mold is broken away, revealing the cast part. This part may require additional finishing processes, such as machining or grinding, to achieve the desired surface quality and dimensional accuracy.

Advantages of Metal Sand Casting

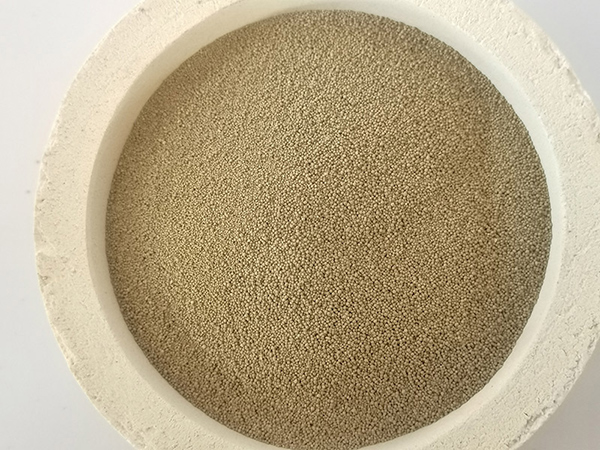

metal sand casting

One of the primary advantages of metal sand casting is its ability to accommodate a wide variety of metal alloys, making it suitable for diverse applications

. Additionally, the sand used in the molds is relatively inexpensive and can be reused multiple times, adding to the cost-effectiveness of the process.Sand casting is also highly flexible, allowing manufacturers to create intricate designs and large parts that would be difficult or impossible to achieve with other forming techniques. This makes it especially popular in industries such as automotive, aerospace, and arts and crafts.

Applications of Metal Sand Casting

Metal sand casting sees extensive use across a myriad of industries. In the automotive sector, it is commonly used to produce engine blocks, transmission cases, and other critical components. In aerospace, lighter alloys are used to create parts that must withstand high stress while being as lightweight as possible. Moreover, the art sector utilizes sand casting for creating sculptures and intricate designs, showcasing the process's versatility.

Conclusion

In conclusion, metal sand casting remains a fundamental manufacturing process due to its affordability, adaptability, and capacity to produce complex shapes. As technology advances, the integration of innovations such as 3D printing and computer-aided design (CAD) continues to enhance the capabilities of sand casting. This ensures that this age-old technique will remain relevant and effective for years to come. Whether in the production of large industrial components or unique artistic pieces, metal sand casting is a vital process in many fields.

Post time:11 月 . 04, 2024 14:27

Next:Innovations and Advances in Sand Casting Techniques for Modern Manufacturing