4. Sand Integration Gradually add the prepared sand into the mixed resin, stirring gently. This prevents clumping and ensures even distribution. Consider layering the sand with other decorative elements for enhanced visual depth. 5. Pouring the Mixture Carefully pour the resin-sand mixture into the mold. Use a heat gun or torch to remove surface bubbles, holding it a short distance above to prevent scorching. 6. Curing Allow the resin to set undisturbed for the recommended curing time, typically 24 to 72 hours. Maintain a stable temperature and humidity for optimal results. 7. Demolding and Finishing Once fully cured, gently demold the piece. Sand rough edges with fine-grit sandpaper. For a glossy finish, apply a thin layer of resin or use a polishing compound. Common Challenges and Solutions Bubbles Persistent bubbles can mar the final piece. Thoroughly degas the resin with gentle heat and consider introducing the sand under low vibration to aid in bubble release. Color Changes Sand can sometimes cause unexpected discoloration. Test small batches ahead to gauge interactions between the sand and resin. Breakages and Chips Improperly cured pieces are prone to fragility. Follow curing instructions meticulously and consider reinforcing larger projects with fiberglass mesh. Ensuring Long-Lasting Results To maintain the integrity of your sand and resin creations, avoid prolonged exposure to direct sunlight, as UV rays can cause yellowing. Regularly clean with non-abrasive cloths and mild soap. If used in functional items like countertops, reseal periodically to preserve gloss and water resistance. Conclusion Casting sand in resin inspires creators to blend texture and translucence into stunning art pieces. By adhering to the best practices outlined here, both beginners and seasoned artisans can harness this technique, crafting pieces that are as enduring as they are captivating. Through detailed preparation and a keen eye for detail, your resin creations with sand can transform into extraordinary fixtures, showcasing your craftsmanship and creativity. Post time:1 月 . 31, 2025 00:35

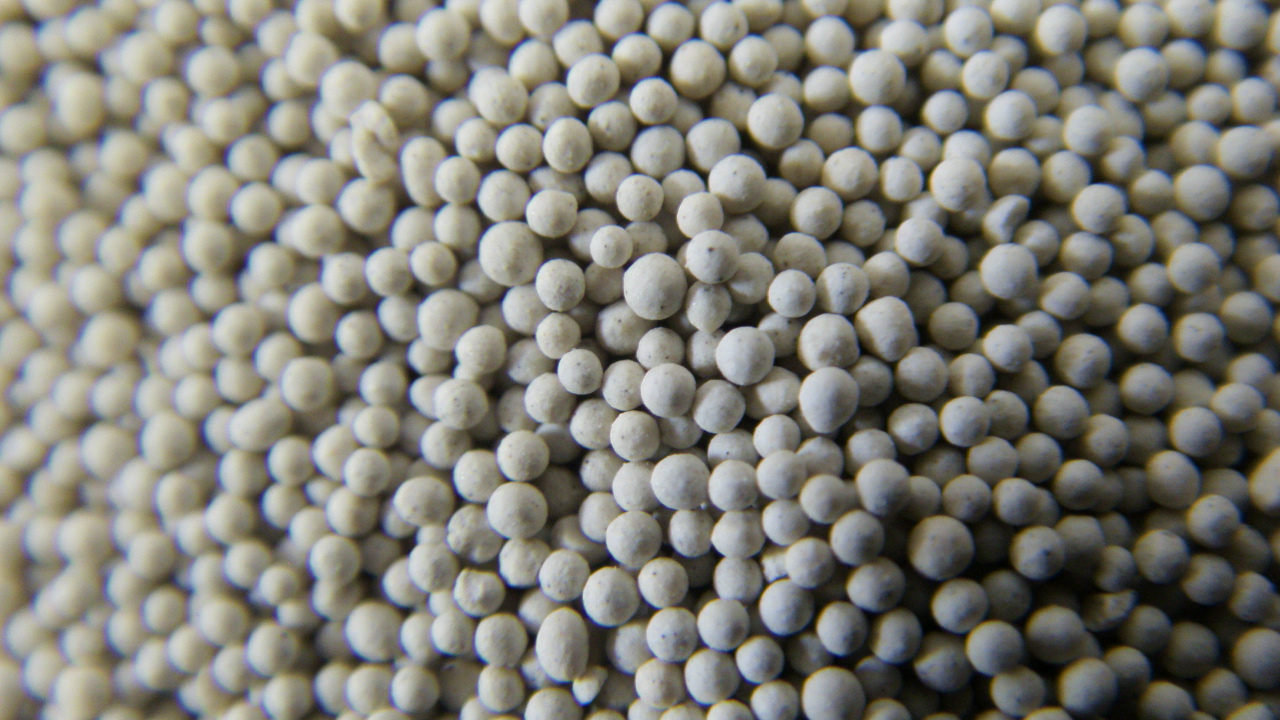

Next:Spherical Ceramic Sand for Foundry