Foundry Sand Testing Ensuring Quality in Metal Casting

Foundry sand testing is a critical process in the metal casting industry, essential for ensuring the quality and consistency of castings produced using sand molds. Foundry sand, typically composed of silica, is the primary molding material for producing metal components in foundries. The quality of this sand directly impacts the integrity of the final cast product, making testing procedures vital.

The Importance of Foundry Sand

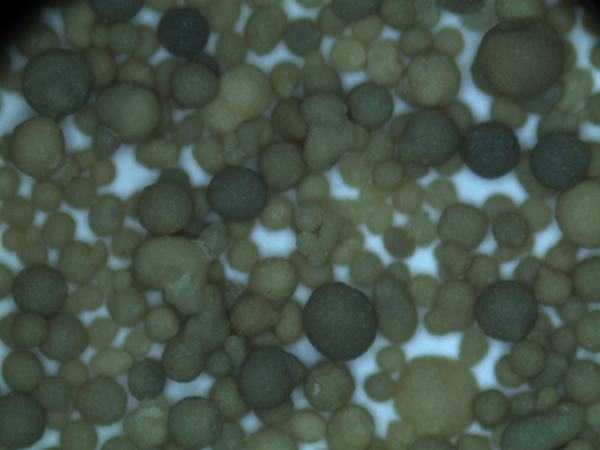

The primary function of foundry sand is to create a mold for metal casting. Its unique properties, such as grain size, shape, and surface texture, significantly influence the casting process and the characteristics of the final product. When the sand is improperly tested or of poor quality, it can lead to defects like mold collapse, sand inclusions, or dimensional inaccuracies. These defects not only compromise the quality of the cast parts but can also lead to increased production costs and delays.

Key Tests for Foundry Sand

Due to its significance, several tests are conducted to evaluate the properties of foundry sand

. These tests can broadly be categorized into physical, chemical, and mechanical properties.1. Grain Size Distribution The particle size of the sand affects its permeability and compactability. A sieve analysis is performed to determine the grain size distribution, ensuring the sand composition is suitable for casting applications.

2. Plasticity Index This test measures the plasticity of the sand, which is essential for moldability. A high plasticity index indicates that the sand can be easily shaped and will maintain its form during casting.

3. Moisture Content The moisture content of the sand affects its strength and thermal properties. Testing the moisture content ensures that the sand mix is optimized for binding, which is crucial for achieving high-quality molds.

foundry sand testing

4. Permeability Permeability tests assess how well gases can pass through the sand mold. Adequate permeability is vital to allow gases generated during the casting process to escape, preventing defects such as blowholes.

5. Compaction The ability of the sand to compact is essential for creating sturdy molds. Compaction tests measure how well the sand can be packed down, which influences the mold’s strength and resistance to deformation.

6. Thermal Conductivity Since metal is poured at high temperatures, testing the thermal conductivity of sand is crucial. This property affects how heat is transferred during the casting process, influencing the quality of the final product.

Benefits of Proper Sand Testing

Implementing rigorous sand testing protocols offers several benefits to foundries. First and foremost, it helps in maintaining high-quality production standards. By identifying issues related to sand quality early in the process, manufacturers can reduce the likelihood of defects and rework, thereby saving costs.

Moreover, consistent sand testing leads to improved operational efficiency. Foundries can optimize their sand mixes based on test results, thus streamlining the casting process. This not only enhances productivity but also improves the overall quality of the cast products.

Conclusion

In conclusion, foundry sand testing is an indispensable part of the metal casting process. By rigorously assessing the physical, chemical, and mechanical properties of sand, foundries can ensure that they produce high-quality, defect-free castings. As the demand for precision-engineered components continues to rise, the importance of effective sand testing will only grow, paving the way for advancements in casting techniques and materials. Investing in quality control through comprehensive sand testing not only safeguards the integrity of cast products but also bolsters the confidence of clients in the foundry's capabilities.

Post time:10 月 . 07, 2024 11:18

Next:sand casting cost