Casting Sand for Sale An Essential Component in Foundry Operations

Sand casting is one of the oldest and most widely used metal casting processes. This technique involves pouring molten metal into a mold made from a sand mixture, allowing it to cool and solidify to form a specific shape. One key ingredient in this process is casting sand, and the demand for high-quality casting sand has led to a vibrant market for its sale. This article explores the significance of casting sand, its types, applications, and market dynamics.

Importance of Casting Sand

Casting sand serves as the primary molding material in sand casting processes. Its ability to withstand high temperatures, mold into complex shapes, and provide a good finish plays a critical role in the efficiency and quality of metal castings. The performance of casting sand directly influences the productivity and economic viability of foundries.

The primary properties that make sand suitable for casting include its grain size, permeability, refractoriness, and cohesiveness. Fine sands are preferred for intricate designs, while coarser sands are used for larger components. Additionally, the sand must be able to retain its shape during the pouring of molten metal and cool down to allow easy removal of the casting.

Types of Casting Sand

The most common types of casting sand include

1. Silica Sand This is the most prevalent type of casting sand due to its abundance, high melting point, and suitable grain size. Silica sand is primarily composed of silicon dioxide and is widely used in both ferrous and non-ferrous metal casting.

2. Chromite Sand Known for its exceptional thermal stability and resistance to high temperatures, chromite sand is often used for casting high-alloy steels, nickel, and titanium alloys. Its high density and minimal expansion during heating make it ideal for high-precision castings.

3. Zircon Sand This sand has a high melting point and excellent resistance to thermal shock, making it suitable for casting non-ferrous metals, especially those with high melting points. Zircon sand is also less chemically reactive than silica, reducing the chances of defects in the casting.

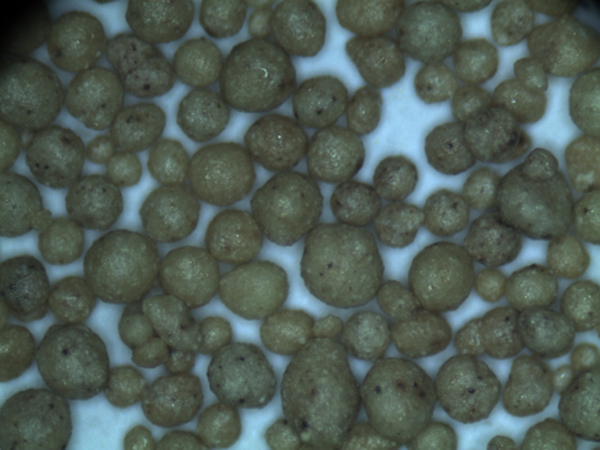

casting sand for sale

4. Olive Sand This naturally occurring sand is primarily used for high-precision molds. Olive sand is notable for its unique texture and high density, which contribute to excellent mold strength and durability.

Applications of Casting Sand

Casting sand finds applications across various industries, including automotive, aerospace, and construction. In the automotive sector, casting sand is crucial for producing engine blocks, transmission housings, and other complex parts. The aerospace industry relies on high-quality casting sand to manufacture lightweight, high-strength components that meet strict safety and performance standards.

Additionally, foundries producing architectural and artistic metalwork utilize casting sand to create intricate designs and structures. The versatility of casting sand supports a range of applications, making it a key factor in the metalworking industry.

Market Dynamics

The market for casting sand is dictated by several factors, including the demand for metal castings, technological advancements, and environmental regulations. As industries continue to expand, particularly in emerging economies, the need for efficient casting processes is on the rise. This demand has encouraged suppliers to improve the quality of casting sand and develop sustainable mining practices.

Additionally, technological advancements in sand recycling and reclamation have transformed the market landscape. Foundries are now able to reuse casting sand, which reduces waste and lowers operational costs. The integration of eco-friendly practices has become a significant selling point for suppliers aiming to meet modern environmental standards.

Conclusion

In conclusion, casting sand plays a vital role in the metal casting industry. Its varied types, unique properties, and essential applications make it indispensable for foundries around the world. As industries continue to evolve and demand high-quality castings, the market for casting sand will likely expand, bringing forth new opportunities and challenges. Investing in advancements in sand quality and sustainability will be crucial for suppliers to remain competitive in this dynamic marketplace. With continuous innovation and adherence to environmental standards, casting sand continues to be a cornerstone of manufacturing excellence in the metalworking industry.

Post time:10 月 . 11, 2024 12:18

Next:3D Printing Techniques for Custom Sanding Machines and Their Applications